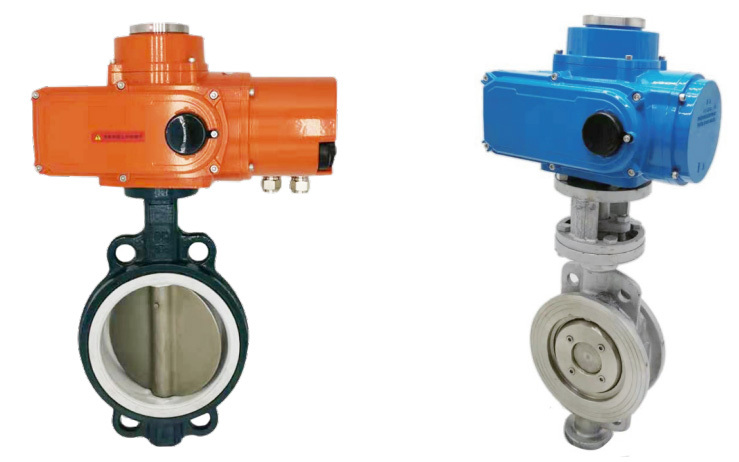

BH Precision Mini Electric Actuator

The micro electric actuator is an economical product that highlights the advantages of compact structure, simple transmission, reliability, small size, and light weight, while meeting the basic main usage functions. It is especially suitable for the automatic control of various small-diameter valves.

- Commodity name: BH Precision Mini Electric Actuator

1. Product Overview

The compact electric actuator is an economical product that highlights the advantages of a compact structure, simple transmission, reliability, small size, and light weight while meeting the basic main usage functions. It is especially suitable for the automatic control of various small-diameter valves. This series of electric actuators uses die-cast aluminum alloy housing and shell, with a powder coating on the surface, making it suitable for relatively harsh working environments. The protection level of the shell can reach IP68, and the explosion-proof level can reach Ex db IIB T4 Gb. It can achieve various working modes such as switching and adjusting, and adopts a standardized connection design, allowing for easy assembly with various valves. It complies with the technical standard JB/T8219-1999 "Electric Actuators for Industrial Process Control and Control Systems."

2. Structural Features

1. The product has a compact structure, small size, light weight, aluminum alloy shell, and powder coating on the surface.

2. The transmission gears are processed in an integrated manner, with high dimensional accuracy. The gears undergo vacuum quenching treatment, resulting in high surface hardness, no deformation, and excellent transmission strength and wear resistance.

3. The built-in motor stator is conveniently located inside the gearbox for heat dissipation and uses F-class insulation, allowing it to withstand higher starting frequencies.

4. Multiple control methods can be freely selected. The built-in amplification module can easily meet various control requirements. The matching magnetic encoder enables intelligent integrated control, and there is an LCD display window and external operation knob for non-intrusive settings.

5. An independent wiring chamber can meet dual sealing requirements.

3. Product Technical Parameters

1. Input control signal: A) Analog signal 4-20mA, B) Passive contact control

2. Input channel resistance: 250 ohms

3. Feedback signal: A) 4-20mA, B) Passive contact signal for fully open and fully closed positions

4. Basic error 1.5%-2.5%.

5. Shell protection level IP67.

6. Motor insulation class F.

7. Power supply voltage AC 220V +10%-15%, AC 380V ±10%.

8. Operating environment temperature: -20-70℃.

9. Operating environment humidity ≤95% without condensation.

10. The explosion-proof level can reach Ex db IIB T4 Gb.

4. Product Specification Model

| Model |

Torque (Nm) |

Motor Power (W) |

Stroke Time (seconds) |

Rubber Butterfly Valve |

Ball Valve |

Hard Sealed Butterfly Valve |

| BH-10 |

100 |

25 |

28 |

DN80-DN100 |

DN32-DN40 |

DN65-DN80 |

| BH-16 |

160 |

30 |

28 |

DN125-DN150 |

DN40-DN65 |

DN80 |

| BH-25 |

250 |

45 |

24 |

DN150-DN200 |

DN65-DN80 |

DN100-DN150 |

| BH-50 |

500 |

70 |

24 |

DN200-DN250 |

DN80-DN100 |

DN150-DN200 |

| BH-100 |

1000 |

100 |

42 |

DN250-DN350 |

DN125-DN150 |

DN250-DN300 |

| BH-200 |

2000 |

120 |

42 |

DN350-DN450 |

DN150-DN200 |

DN350-DN400 |

5. Usage Requirements

Operating Environment

1. The design shell protection level of this series of products is IP67, suitable for indoor and outdoor use under general conditions, with an environmental temperature of -20-60℃. If the equipment is subject to immersion, an IP68 model should be selected. If the pipeline medium temperature is relatively high and may conduct to the equipment body, an additional connecting bracket should be used during installation to reduce heat conduction.

2. When connecting the power line and control cable to the actuator, extra care should be taken to prevent external water from creeping into the body and external moisture from entering the body.

Stroke and Control

1. The effective stroke of the rotational motion of the control object (valve, damper, etc.) and the actuator (0-90 degrees) should be consistent, and over-stroke usage is not allowed. It is necessary to ensure that the mechanical zero points correspond to each other. If a lever connection is used, the motion trajectory of the connecting rod should be in a parallelogram state.

2. The stroke protection of the actuator consists of signal (4-20mA), limit switch, and mechanical limit, with a small margin left between the three protections.

3. Before using the equipment, check the operating environment (especially in explosion-proof locations), power supply, and control method to ensure consistency. Pay attention to the accuracy of wiring, especially ensuring that the power and control lines are not connected incorrectly.

4. Remote control signals should not use strong electrical control. The product manual should be read carefully before using the equipment.

6. Product Installation

To ensure accurate control, the matching precision of the transmission parts should be improved to prevent a decrease in transmission accuracy due to excessive gaps. Severe cases may lead to the product not functioning properly.

1. The machine can be installed arbitrarily, with no unreasonable installation positions. The outlet hole should face down as much as possible.

2. The surrounding environment of the equipment should avoid heat sources, strong magnets, and corrosive gases. If it is difficult to avoid, appropriate isolation measures or special customized products should be taken.

7. Maintenance and Care

Since the sealing material used in the product is rubber, attention should be paid to replacing failed seals after long-term use. To ensure the product has a sufficient service life, a working torque with a certain margin should be selected for frequently operated locations.

1. A suitable working environment will increase the product's service life.

2. Valves that are not operated for a long time should be actuated periodically to prevent rust and jamming of internal components.

3. Regular checks should be conducted on fasteners, wiring, seals, and other parts in environments with long-term vibrations.

Message